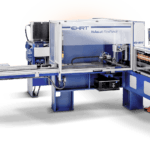

Compact CNC Busbar Punching Machines

The EHRT FlexPunch & FlexPunch Compact punching machine provides fast, highly-accurate punching of copper bus bar and other flat bar materials. With tooling to create holes, slots, chamfers, and more, it is the perfect 40-ton and small run punching machine.

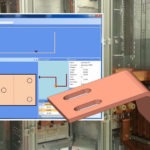

In addition, thanks to our exclusive PunchPro nesting software and the accuracy of our machines, the FlexPunch line of punching machines will help your business reduce costly scrap and maximize efficiency. Check out our article on Punching vs Drilling Busbar to learn more!

FlexPunch and FlexPunch Compact Product GuideSingle Tap Thread Forming Station

Features

- Punch copper busbar, aluminum busbar and steel bar

- For material ranging from 1/8″ to 5/8″ thick

- Create circular holes, slots, chamfers, radiuses, and more, in a range of sizes

- Lateral clamping allows the machine to cut almost the entire workpiece, even the border

- Fast setup time with PowerCut software

- Nesting optimization with PunchPro software

- CNC tooling rail with up to 4 or 10 positions

- Quick-change punch tools

- 3-in-1 Multi tool

- Perfect for small and medium runs of parts

- 3/16” max capacity in steel

Models

- EHRT FlexPunch

40 ton, with 10 Quick change punch tools - EHRT FlexPunch Compact

40 ton, with 4 Quick change punch tools

QuickChange System by EHRT

QuickLock System by EHRT PDF Document

Specifications

FlexPunch

- 9 punching + 1 cutting

- Punching up to 1.26” diameter

- Available tooling includes circular holes, slots, chamfers, nibbling, rounding, tapping, countersinking and more

Punching Force

- 40 tons

Workpiece Thickness

- .12-.39”, steel

- .12-.63”, copper

- .12-.63”, aluminum

Workpiece Width

- .59-8”

Positioning Accuracy

- Within .004”

Controls

- Industrial PC with Windows 7 or later

- PowerCut punching software

- PunchPro nesting software

- SQL database for large data sets

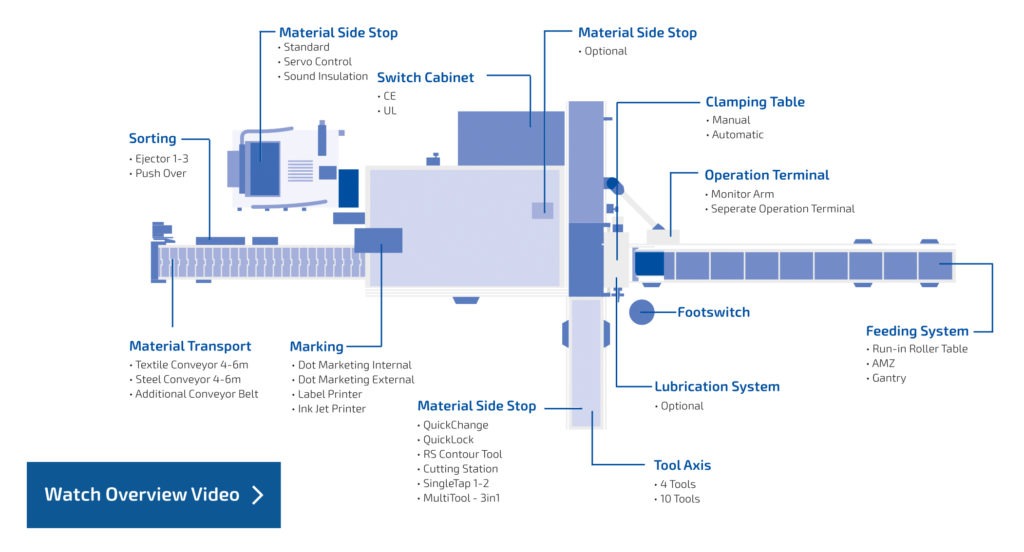

Options

- Automatic feeding system

- Sorting & additional conveyors

- Multiple part marking options

- Thread forming

- Profile punching

- Variable speed

- PunchPro nesting software